The world of electric mobility, from electric scooters to bicycles, stands at the precipice of innovation and quality. However, at the core of every premium product, there is a secret – raw material sourcing. With the boom in electric mobility products, quality becomes paramount. A cornerstone of this quality is the raw material we choose.

Navigating the sourcing landscape of electric scooters can be a hard journey. But with the right choices, we can still pave the way to creating world-class products that are both durable and efficient.

Sourcing isn’t just about finding materials; it’s about ensuring these materials align with the brand’s ethos, quality standards, and overall product vision.

What Makes Raw Material Sourcing a Game Changer for Electric Scooters and Bicycles?

The right materials can transform a decent product into a groundbreaking one. For example, the lightweight but robust materials ensure the agility of our electric scooters while providing stability. It’s this delicate balance that can only be achieved through precise sourcing.

Materials play a key role in battery efficiency, product longevity, and the overall riding experience. When sourced meticulously, they lay the foundation for a product that not only meets but often exceeds customer expectations.

How Can Precise Sourcing Reflect in the End Product?

Every material used in a product has a story – where it was sourced from, its quality parameters, and how it adds to the product’s integrity. When companies like us, DriveTron, invest time and resources into sourcing, it translates into tangible benefits for the end-user: longer product life, optimal performance, and an unparalleled riding experience.

To put things into perspective, consider the difference between a product made from sub-par materials that wear out quickly versus one constructed from premium, carefully-sourced materials. The difference is totally different.

What Challenges Do Companies Face in Raw Material Sourcing?

The journey of sourcing is full of challenges. From identifying authentic suppliers to ensuring the materials adhere to global certification requirements, there’s no end to the hurdles. Moreover, with the global market’s ever-evolving nature, staying updated with the latest materials and technologies becomes crucial.

For brands that export globally, ensuring the materials meet multiple national market certifications can be a huge task. But it’s a challenge we embrace head-on, for our commitment to quality is firm.

Why Do We Prioritize Strict Control Over Material Quality?

At DriveTron, we’ve always believed in the philosophy of ‘quality over quantity’. Our products aren’t just another model in the market. They stem from independent research and development, with every component handpicked to align with our vision.

This strict control over material quality isn’t just about maintaining our brand reputation. It’s about delivering on our promise to our customers – the promise of quality, durability, and excellence. After all, a product is only as good as the materials it’s made of.

How Does Efficient Communication Play a Role in Sourcing?

Communication is the bridge between a vision and its execution. In the world of sourcing, efficient communication can be the difference between securing the best materials and settling for the ordinary. At DriveTron, we pride ourselves on our ability to communicate efficiently, ensuring that our suppliers understand our standards, expectations, and vision.

This proficiency in communication isn’t just about talking; it’s about listening. It’s about understanding market needs, predicting trends, and adapting swiftly.

So we are always offering solutions to our customers, always getting things done!

What Measures Do We Need To Take to Ensure Reliable and Quality Sourcing?

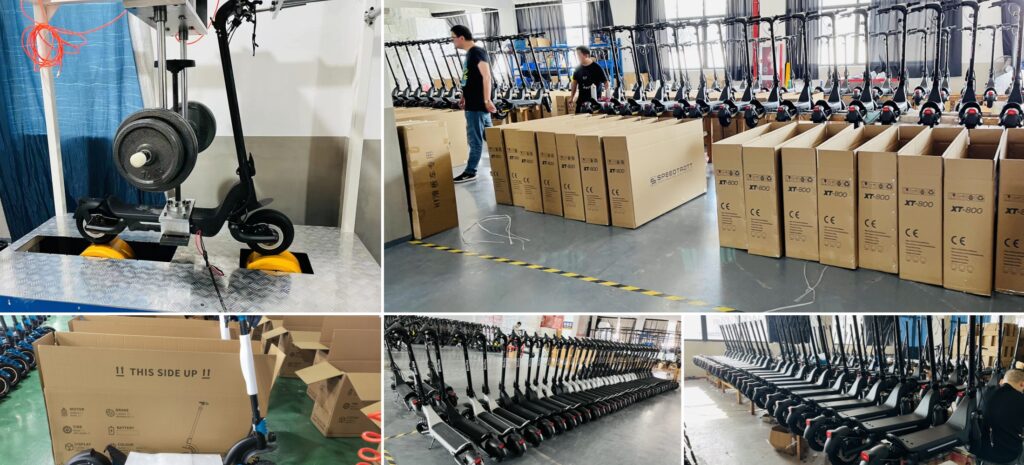

Our journey begins with rigorous research. Identifying and designating suppliers for our core spare parts is a detailed process, backed by data, trends, and industry insights. But it doesn’t stop only there.

We continually invest in our molds, develop instruments in-house, and collaborate closely with our outsourcing factories. This synergy ensures that the final product, whether it’s an electric scooter or a bicycle, resonates with our signature of quality.

Conclusion: The Foundation for a Sustainable and Quality Electric Mobility Future.

In the dynamic world of electric mobility, the race isn’t just about being the fastest or the most innovative. It’s about building a legacy of quality, trust, and excellence. At DriveTron, raw material sourcing isn’t just a task; it’s a commitment. A commitment to every customer who chooses us, trusting our vision and our promise. And as we move forward, this bedrock of quality sourcing will continue to fuel our journey, one ride at a time.